Showroom

Extrusion machines are essential in plastic processing industries for shaping materials through a continuous molding process. They ensure uniformity, efficiency, and precision in producing pipes, profiles, and sheets. Designed for high output and durability, these machines support various applications across PVC, HDPE, and other thermoplastic manufacturing lines.

Screw barrels are vital components in plastic and rubber extrusion and injection molding. They facilitate uniform material mixing, melting, and forwarding within the machine. Manufactured with wear-resistant materials, screw barrels ensure long-lasting performance, consistent output quality, and efficient processing across a range of polymers and extrusion applications.

Die heads are crucial in forming the final shape of extruded plastic materials. They determine the profile, wall thickness, and diameter of pipes and profiles. Designed for precision and uniform flow, die heads are used in PVC, HDPE, and other polymer extrusion systems to ensure optimal product quality.

PVC pipe plants are comprehensive setups designed for manufacturing high-quality PVC pipes in various diameters and thicknesses. These plants include extrusion machines, die heads, cooling systems, and cutting units, ensuring smooth, continuous production. They are widely used in irrigation, plumbing, and drainage applications across industrial and domestic sectors.

PVC garden pipe making machines are specialized units for producing flexible, lightweight garden pipes. Designed for smooth extrusion and coiling, these machines ensure high production efficiency and uniform pipe quality. Commonly used in agricultural and domestic applications, they support various pipe diameters and customized production requirements.

Traction machines are used in extrusion lines to steadily pull extruded pipes or profiles through the production process. Built with synchronized speed control and rubberized belts or caterpillar tracks, they ensure consistent pulling force, maintaining shape and surface finish. These machines are vital for ensuring accurate pipe sizing and smooth flow.

HDPE pipe plants are complete production lines designed to manufacture high-density polyethylene pipes used in water supply, gas distribution, and industrial applications. These plants integrate extrusion, cooling, sizing, and cutting systems to deliver high-performance, durable, and corrosion-resistant pipes with varying diameters and thicknesses as per industry standards.

Sizing tanks are used in pipe extrusion lines to shape and cool pipes after they exit the die head. Filled with water and equipped with sizing sleeves, they help maintain dimensional accuracy and surface smoothness. Their stainless steel construction and vacuum compatibility ensure durability and optimal cooling efficiency during production.

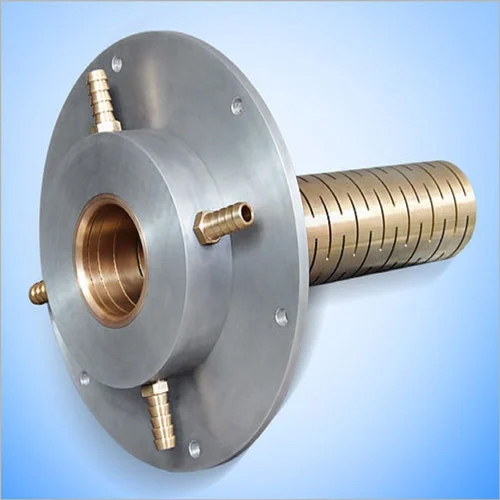

Vacuum sizers are precision components used in pipe manufacturing to maintain correct pipe diameter and roundness. They operate by applying vacuum pressure within the sizing tank to hold the pipe against the sizing sleeve. These tools are essential for achieving uniformity and dimensional accuracy in high-speed pipe extrusion processes.

Tilting machines are used for controlled unloading or positioning of pipes and profiles after cutting or production. Their mechanical or hydraulic systems allow for smooth tilting, ensuring safe handling and collection. Commonly found in pipe plants, they improve workflow efficiency and reduce manual labor in downstream processes.

Screw conveyors are versatile material handling systems used to transport granular or powdered materials in industrial settings. Featuring rotating helical screws within a tube or trough, they ensure smooth, controlled movement of materials. These conveyors are widely used in extrusion, food, cement, and chemical industries for efficient bulk transfer.

Single screws are the core elements in extrusion machines, responsible for conveying, melting, and homogenizing plastic materials. Designed with specific pitch and flight geometry, they offer high output and efficient processing. Single screws are widely used in PVC, HDPE, and other thermoplastic extrusion systems for consistent material flow.

Pipe cutting machines are essential in extrusion lines for cutting pipes to precise lengths. Equipped with rotary or planetary cutting mechanisms, they ensure smooth, burr-free cuts without damaging the pipe surface. These machines are synchronized with the production line speed and are ideal for PVC, HDPE, and garden pipe applications.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free